A stud frame was built for the bathroom enclosure and then fitted with water resistant wallboard on the inside and finished with cladding on the outside. In this post I’ll cover:

- Building the stud frame for the bathroom/shower enclosure

- fitting waterproof wallboard

- fitting toilet

- fitting shower/bathroom door

- 12V light

Note: this was updated on 15th May 2015

Matt came round to help me, making it up as we went along, it was finished in a day. Here’s how we did it:

Build a stud frame

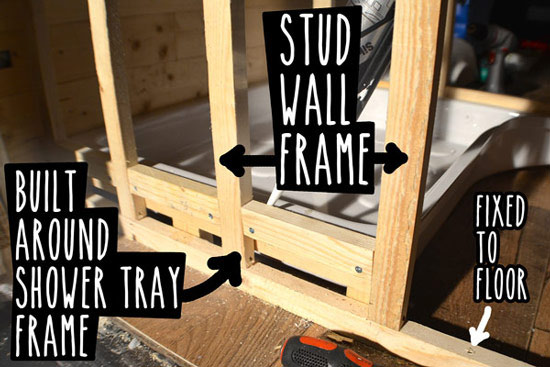

The stud walls for the bathroom were built from the floor, fixed around the edges of the wooden shower tray frame, up to the ceiling using vertical lengths of pine

It’s important to have a strip of wood where the stud wall ends, to give the wallboard a solid edge to fix to. This is especially important for the bottom, where it is more likely to be kicked.

The toilet I’m using is designed to sit in a shower room and get wet. It has a rubber seal around the back where it presses against the wall to make it watertight. But the wall it sits against must be solid and straight to make this a good seal. I had to make sure that the wall studs landed directly behind where this rubber seal to give the wall enough support.

I completed the stud wall frame by fixing horizontal lengths of wood between the vertical supports. The large rectangle near to the top of the stud frame in this picture will be for a window.

Cut and fit the wall boards

With the frame in place and feeling fairly solid, the wallboards need to be cut to size and glued to the frame.

The tricky part here was fitting the wallboard to the curved profile of the van wall. I’m not sure how it would be normally done (by a professional) but here’s how I did it. I will try to explain: I made a marking jig using a length of wood with a hole drilled in to hold a pencil (the tip of the pencil goes through to the other side of this bit of wood). With the wallboard (not yet cut) at 90 degrees to the van wall, I used my marking jig to draw the curve on to the board to be cut. One end of the jig remains in contact with the van wall and it is moved up (or down) with the pencil in contact with wallboard–the white area to the right of this picture.

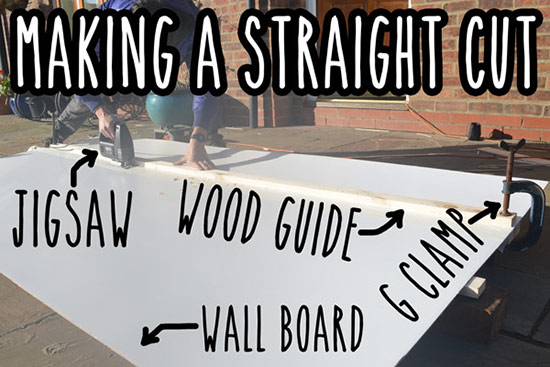

I used a jigsaw to cut out all the sections of the wallboard. You have to be careful when cutting this kind of laminated wall board though, because the laminate coating chips and cracks easily at the edges. I put a tiny bit of WD40 on the blade of the jigsaw to stop this happening and to get nice clean cuts–as well a not going too fast.

If you don’t have a proper table saw to cut straight sheets of wood (like I didn’t), you can just fix a straight length of wood to the sheet with a G-clamp at each end and used this as a guide for the jigsaw. You’ll need to use something to keep the sheet of wood off the ground (making enough clearance for the jigsaw blade). I used a couple of lengths of wood resting on bricks.

With the sections of wallboards cut, I put them in place to check they fit correctly. For most of the boards I’d have to sand or shave a little bit off the edges to get a perfect fit. Once I was happy with the fit, I stuck the boards down to the inside surface of the stud frame using PU adhesive. I used the PU adhesive for this rather than wood glue, simply because wood glue requires a lot of pressure on the two pieces to make a strong bond and is not tolerant to any slight unevenness.

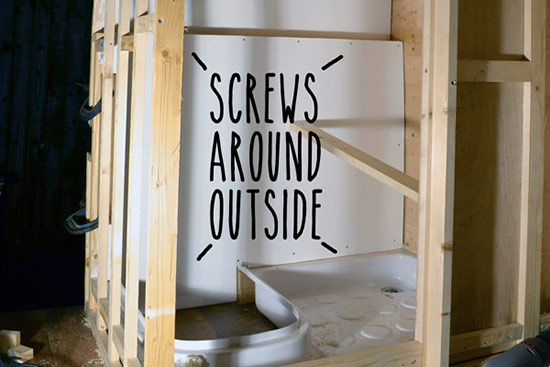

I decided at last minute to use screws around the edge of each wallboard to make sure it was properly held in place and flat against the stud frame. I countersunk the screws and covered the heads with white silicone. I could have also just taken the screws out when the glue was dry and filled the hole with silicone–that would probably be a bit neater. Once all the boards were fixed in place, I ran mould resistant silicone into all the corners.

The image below shows the finished enclosure walls. Now the walls need to be cut out for the toilet cassette access and window at the back.

Fit toilet Cassette access door

The compartment where the cassette is stored should be completely sealed off from the living space (because of smells). I used some adhesive rubber strip (sold as ‘door weather strip’ in my local DIY store–Wickes) and stuck this around the opening. I made the door from some 9mm plywood and two small cabinet hinges. See images below.

Finish around the door frame for water tight seal

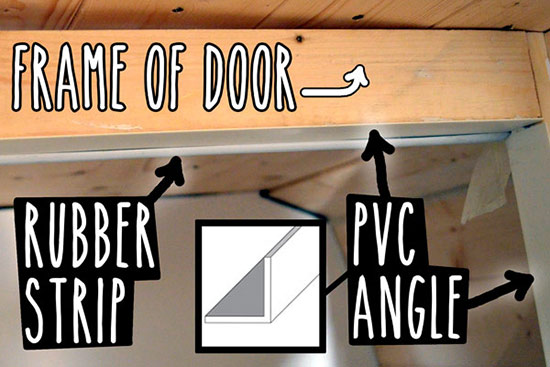

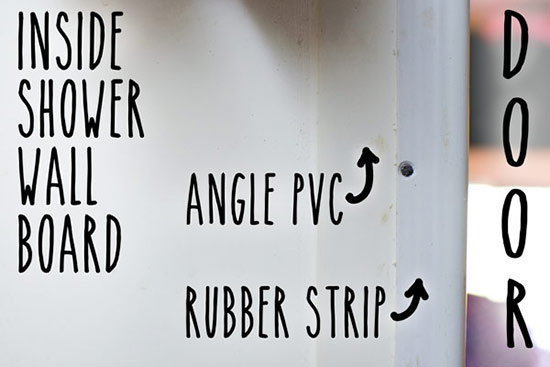

At this point, the wood for the doorframe is bare and needs to be finished off to protect it against water. I used four lengths of angled PVC trim and glued this around the inside corner of the doorframe. This is will stop water coming into contact with the wood, and also gives a nice straight finish around the frame.

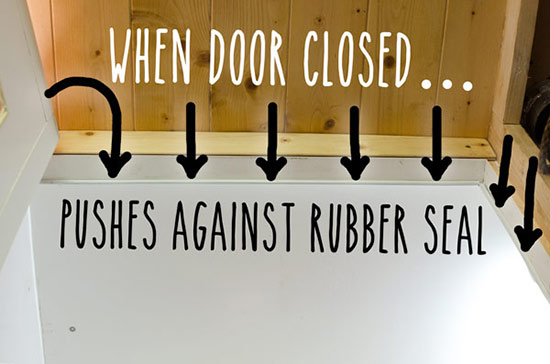

I also fitted a rubber seal around the door so water doesn’t get all over the floor of the living area when having a shower. To do this I modified a PVC sealing strip so it could be fixed around the doorframe. The flat part of this strip is made from PVC and the cylindrical part is made of rubber.

The image below shows how I modified the strip. I fixed this flat part with glue and small nails around the inside of the doorframe, so that the rubber part protrudes the edge of the frame for the door to press up against when closed.

This is a rather crude way of creating this door seal, but it was more the case of using the materials I already had lying around. The seal does a good job quite but if I were to do it again I’d maybe spend a bit more time looking at other solutions.

Construct and fit bathroom Door

With the frame complete, I made a door to fit. This is just a similar construction style to the bathroom walls. It’s just a stud frame with cladding on one side and wallboard on the inside.

1. Construct frame

I started by constructing the frame structure of the door by joining four pieces of 47x22mm pine and reinforcing with a 45º corner piece on the inside of each corner. I made sure to only pick out the really straight lengths from the pile to get a good square and flat door. See image below.

2. Fit board–front and back

For the side of the door facing into the shower enclosure, I used the same white wallboard as used for the inside of the enclosure walls. The other side of the door that faces into the van is cladded with the same 9mm pine cladding as I used for the lining the van interior walls.

I cut a rectangle out for a window in the wallboard and glued a sheet of Perspex (aka Plexiglas). This is so the light from outside can come in from the back window, through the bathroom and into the van living area

3. Finish edges

With the cladding fixed to one side of the door and the wallboard fixed to the other side, I sanded the edges to get a smooth and straight edge all around. See image below.

I hung the door using two T-hinges (the type that are often used for the doors of sheds) from the corner of the bathroom simply because this was the strongest part of the structure. The top hinge is mounted a 14cm down from the top of the door and the bottom hinge is mounted 22cm up from the bottom. This is to account for the optical illusion that occurs when looking down at the hinge when standing–the viewing angle skews the perception of distance.

To finish the door I fitted the corners with the same right angle PVC strip as I showed you earlier around the frame for the door. This stops the wood from getting wet and also gives a nice straight edge to press up against the rubber seal on the inside of the door frame, to make the waterproof seal. I also fitted the handles and ball catch.

Now the bathroom enclosure is complete you can see how the light from outside comes in through the back window of the van, into the Perspex window at the back of the bathroom and then through the bathroom door into the van.

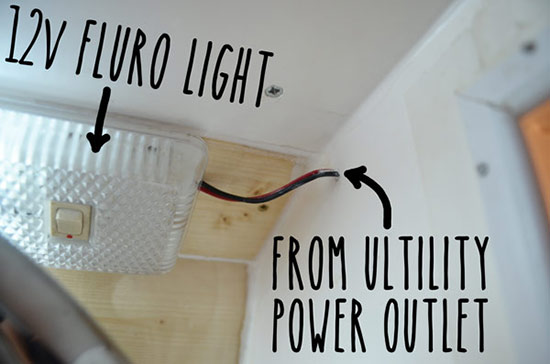

Install bathroom light

For the light in the shower/toilet room, I used 12V fluorescent strip light that came out of a caravan. This type of light uses more power (8W) than an LED equivalent, but this is still fairly low power, and since this will only be used for a few minutes at a time, the power saving advantages of and LED light would be negligible.

Note: This type of light turned out to be a good choice. It is easy to fit and doesn’t require any cutting. The built in switch meant I didn’t have to go to the trouble wiring and mounting a separate switch. Another bonus is light projection from this is also a lot less directional than LED and nicely lights up the whole shower/toilet enclosure.

Now see post on installing the shower