Before building the frame I need to think about some of this stuff:

- the overall look of the cladding–Ideally It needs to follow the bowed shape of the van body

- van space–this could easily take off a few inches of space all around. Head space is critical and I’d rather not loose any at all.

- needs to be enough of a gap for a decent amount of insulation

- where to run cables

- any fixing points I may need for shower, kitchen, bed, benches etc so the frame behind the cladding can be strengthened

I need to design the frame as simple and light weight as possible whilst taking the above into account.

Here’s how I made the frame for the cladding walls

The cladding will be screwed to vertical wooden beams that I screwed into the existing metal struts of the van. I followed the curve of the van as much as possible to use all of the space–and it looks a lot better than a straight wall. There are a total of eight verticals (four on each wall) and four horizontal pieces on the ceiling.

1. The walls

For the vertical beams I used lengths of pine that were just thin enough to bend to the curve of the van wall, but still strong and deep enough for the cladding to screw into. I screwed these into the existing steel ribs of the van at the points marked with the arrows.

2. The ceiling

I could not afford to loose any more height in the van so instead of fixing the wooden horizontal pieces on top of the vans metal ribs (like the vertical bits), I fixed two pieces either side. The horizontal pieces are completely flush with the existing metal struts that go across the roof, so no space is lost.

This wood I used for the roof beams was a bit deeper (to make it level with the metal strut) so I cut slots at even intervals to help them bend easier to the curve of the roof as shown in the picture.

Ignore the pink colour. I was recycling wood.

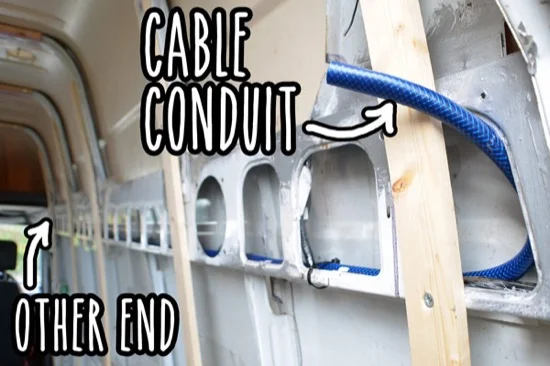

3. Install wire conduit

This is a good time to install any wires and cable that need to be hidden. At this point I didn’t know where the wires would be going so I installed some flexible hosepipe to use as cable conduit. This let me install wires behind the walls later, by just feeding them through the pipe after squirting a little WD40 inside to ease the wire through.

I ran two lengths of pipe across the ceiling (one at the front and one at the back) and one length down each side of the van wall from the front to the back. The picture shows the one that runs down the right side of the van wall.

Note: I only ended up using one of these conduits (to get the utility cable from one side of the van to the other). It worked well though, and is quite useful if you haven’t thought about the electrical stuff at this stage.

Now see post on fitting cladding