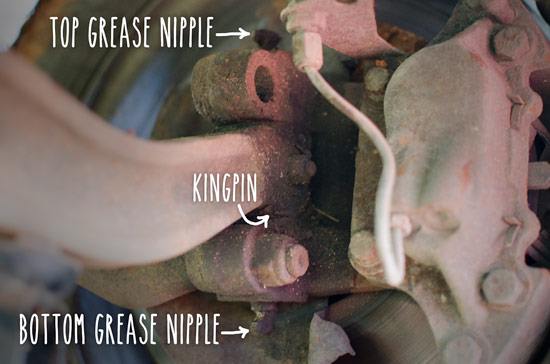

The kingpin (aka swivel pin) is the pivot in the steering mechanism of a vehicle. This component takes a fair amount of stress and can wear out quickly if not regularly greased.

This post goes over how I grease the kingpins on my LDV Convoy van, but the following method applies to pretty much all vehicles with kingpins. This is a simple and quick job (15 minutes max) which will help prolong the life of the kingpins. I do this job once a month as advised by a reader of this blog, who also has the same LDV van.

How to grease your kingpins

1. Jack up

It’s important to use a jack so that the wheel is off the floor with no weight on it. This allows for proper coverage of grease around the kingpin and bearings. Please use a jack big enough for the weight of your van, such as a trolley jack (as in picture below, or a cylinder jack). If you need to go under the vehicle then make sure you use an axle stand for extra safety.

2. Load grease gun

refer to your vehicle manual for the correct type of grease to use. If you don’t know, any kind of CV joint grease will be fine – this is the dark grey stuff.

3. Locate grease nipples

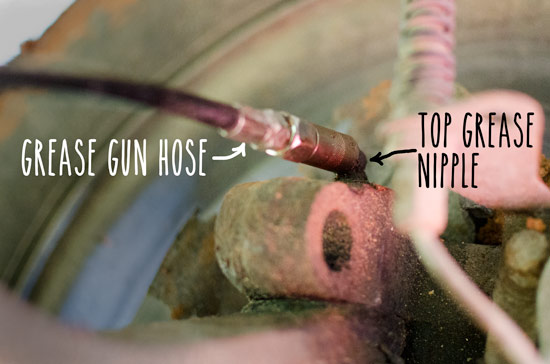

There is usually a grease nipple on the top and bottom of the kingpin assembly. It may be necessary to wipe or clean gently with a wire brush before attaching the grease gun hose.

4. Attach Grease gun

The grease gun attachment just pushes on. If you’re having trouble pushing the gun hose onto the stud, loosen the threaded collar slightly on the end of the grease gun attachment. Once it is pushed on, tighten up the collar for a good seal.